60 CM MIRROR

This one has always been a dream for me. But the prices of the glass!! When I started thinking about a 60 cm, the price of a disk was ca 5000 dollar..

Suddenly, I heard about pyrex glass that was not too expensive. It was available from Newport in California.

April 2004 : The pyrex 610x 45 mm disc arrives from California. It already has a radius of f4.4 . Cost : 980 euro for the disc and 600 euro for transport and taxes.

| Date | Work |

| April 9,2005 | First work is to grind the backside flat. I used a 400x 19 mm float glass disc and carborundum 240 |

| May 13, 2005 | I made a 48×5 cm plaster disc ,cast on the mirror,that was protected by vaseline.I had made a dam of thick cardboard .After a week drying I glued (polyurethane 2 component glue) small tiles (19x19x2 mm) on the plaster .Distance between tiles was 7 mm.. The disc was protected against moisture with 3 layers of varnish.This grinding tool of course has to be made fit on the mirror. The progress is checked with the help of little marks on the tiles made with a waterproof inkStroke : Mirror below ; small W-stroke ; overhang not more than 10 cmCarborundum 180 and 240 ( C180 and C240)The grit is applied as a suspension in water with a little detergent added . It is squirted on the mirror or the tool with a plastic bottle with small opening. I add some after every round. A walk around the table has 8 positions |

| May 16 | C180 finished after 12 rounds . Now C240 |

| May 17 | Ink marks still around on the edge tiles after 7 rounds |

| May 19 | C 240 : ink marks gone after 10 rounds , even near edge |

| May 21 | 45 rounds 240. Only 4 tiles are not ground.I regularly round off the edge of the mirror and the edge tiles with a 400 grinding stone |

| June 1 | Next : C320Done : 100 rounds C320 and 3 rounds with C600 to be able to see and mark some pits on the mirror.The grinding tool is fitting well |

| June 2 | 4 big pits marked within 2 cm of the edge of the mirror.It is quite a heavy job to carry the mirror around! |

| June 11 | Next : C600 : to avoid bigger particles I decant a C600 suspension and use only the upper part. After 200 rounds most marked pits are gone |

| C800 : after 500 rounds I mark some pitsAfter 5 rounds the ink cross on the mirror is already gone.Pits marked after round 59 | |

| June 27 | After 100 rounds C800 and 145 rounds Al-oxyd ( 15 micron microgrit) : all marked pits are gone. I treat the mirrors edge often with a 400 stone |

| June 28 | Pity. I discovered a number of scratches.Back to C800. After 40 rounds scratches still visible |

| June 29 | I return to C500 and 600 ; 800 too fine for these scratches |

| June 30 | After 40 rounds : scratches smaller |

| July 1 | After 80 rounds : scratches have turned into a number of small pits |

| July 3 | After 140 rounds : scratches are gone. To C800; 40 rounds done |

| July 18 | Round 135 : finished. Mirror edge and tool edge(the tiles) rounded with stone 400 |

| July 19 | On to C1200120 rounds; then on to 20 rounds with Al-oxyd microgrit 9 micron and 22 rounds with 3 micron.No pits or scratches visible. |

| POLISHING | |

| This time, I didn’t cast the pitch on a plaster tool but chose for a plywood tool, made of 5 discs of 18 mm plywood (diameter 48 cm). On top of that were glued 2 layers if 3mm thick board ( of dfferent diameter, so as to mimic a convex surface). 2 rectangular wooden blocks are glued to the side of the thick disc. They function as grips while polishing.Around the disc came a cardboard dam and the molten pitch was cast through a nylon stocking onto the wooden base. After the pitch had cooled enough I made cross channels with a 10 mm thick piece of wood. This way of making a pitch lap I read from Dobson’s methods. Fitting the pitch lap to the mirror took some time. I heated the pitch lap with warm water and pressed it with 10 kg. on the mirror. It took several sessions and I had to trim the pitch a numer of times. Pitch squares are 50 mm wide. | |

| Sept. 6 | Start of the polishing. The work is heavy!!. Mirror below . W-stroke with 3-5 cm overhang. It is not going well. Tomorrow I will sratch the pitch squares with a sharp knife to ease the polishing |

| Sept. 7 | Polishing is going much better. 45 min ( 3 periods of 15 minutes) |

| Sept. 11 | Total time : 1h45m. Today 4x 15 minutes. When the pitchlap catches, polishing is very heavy work, despite the handles on the pitch lap. The pitch squares have to be scratched often. |

| Sept. 20 | Total time : 7 hours . It is going well because the temperature is not so high.Reflection test( 25 W clear bulb focussed with 50 mmf2 lens on the mirror) : weak till r=25 cm. Edge area still has a quite strong reflection. |

| Sept. 29 | Total time 12 hour ; 2x 15 min. a day is already quite a job! Afraid of arm injury |

| Oct. 5 | Total time 15 hours ; reflection in last 5 cm still obvious. |

| Oct. 21 | Total time 22 hours. Reflection at edge very weak |

| 25 hours of polishing : stop | |

CORRECTING THE MIRROR

I use the Figure XP program for evaluating the mirror figure

Jan 19, 2006 : I made a 25 cm pitch lap from Gugolz 55 pitch with some turpentine to soften it. I didn’t check out the hardness

Working plan:

- Fit the pitch lap on a 25/5.5 mirror (to get a curve in the pitch))

- Work ceriumoxyd polishing powder into the pitch

- Cut a star form with 8 points in the pitch

- Fit onto the 60 cm and trim the pitch squares.

Step 1 jan. 21 ,2006

I rounded off the mirrors edge with the help of a 400 stone.Start of correction.

1a . 25 cm 8 points starlap with 2kg weight on it

Straight stroke 0-1 cm to the right of the center with 5-7 cm passover: 20 turns ( 8 positions per turn).

5 min cold press after every ten rounds.

1b . Large W with 5-7 cm overhang 2x 1 turn with cold press after every turn around

Step 2

First 10 min warm press with 5 kg, followed by 1 hour coldpress with 2 kg

a. Straight stroke 25 cm lap 0-3 cm from center 3x 10 rounds with 5-7 cm overhang

b. Large W-stroke with 5-7 cm passover 2 rounds with pressing in between

Test : ronchi : sferical with strong TDE ( Turned down edge) . Foucault diffraction ring much brighter on the right side. Also polishing scratches and blotchy surface

Step 3

3a Increase correction

25 cm lap 30 rounds Straight stroke 0-5 cm ; 7-10 cm overhang

3b Large W-stroke, mostly on edge of mirror; 10 cm overhang

Test: TDE ca 5 cm wide

Fouc. Test:

zone 7 : 2.2 mm

Zone 6 : 0,65 mm

Zone 5 : 0 mm

Zone 1 : 0 mm

Step 4

4a . First try to get rid of TDE

- old 10 cm pointed lap( squares are made narrower near the edge) circular stroke on outer zones. Now and then an elliptical stroke to the center

- circular stroke 2-6 cm from edge: 5 turns around

- Dito 2-25 cm from edge: 1 turn around

Total time: 30 min.

4b. Different approach: work with 25 cm eight points starlap (with 2 kg)

- Tangential stroke 4-8 cm from edge : 30 min

- Straight stroke 0-5 cm from Center to increase correction: 2x 15 min with 2 kg

- Large W with 5-7 cm overhang : 3 turns around.

Ronchi: TDE seems to have lessened.Surface blotchy.Pitch too hard?

Fouc:

7 : 1.9 mm

6 : 1. 3 mm

5 : 1.2 mm

1 : 0 mm Getting better!

Step 5 .

jan 25 – 2006

25 cm pitchlap (8 points star) : 10 min in lukewarm water and then 30 min pressing with 5 kg

- tangential stroke 4-8 cm from edge with 2 kg : 15 min

- Straight stroke 0-5 cm from center with 2 kg : 2x 15 min

- large W stroke max 8 cm passover

Test: difficult to perform: the light passes through several rooms . Measurements are impossible if the house is warming up.

Step 6

Jan. 26 ,2006

- Straight stroke with 25 cm lap +2kg ; 0-5 cm from c and 5-8 cm overhang : 3x 15 min (pressing in between, which is always done during long polishing sessions).

- Large W-stroke with 2 kg and 5-8 cm overhang : 5 turns around.

test : Ronchi : looks OK

Fouc. 1 measurement: First with a 7-zone mask

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Measurements | 0 | 0,2 | 0,6 | 1,0 | 1,35 | 1,55 | 2,05 |

| Parabola | 0 | 1.52 | 2.81 | 4.09 | 5.34 | 6.61 | 7.78 |

Step 7.

I trim the old 25 cm pitchlap. The squares are cut in 4. Smaller pitch squares make movement easier!

- 25 cm starlap : straight stroke 0-5 cm from C and 5-8 cm overhang : 50 min

- Large W-stroke concentrating on outer zones ; 5-10 cm overhang : 4 turns around

Test: difficult because of the “clouds”in the lightpath!

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| measurements | 0 | 0,8 | 1,4 | 1,8 | 2,4 | 3,0 | 3,6 |

| parabola | 0 | 1,52 | 2,80 | 4,08 | 5,33 | 6,60 | 7,78 |

Ronchi pattern looks regular

Step 8

Jan. 28, 2006

First, I made a softer 25 cm starlap

- Straight stroke with 2 kg 0-5 cm from C and 5-8 cm overhang

- The same 30 min

- Large W-stroke + 2 kg with 5-8 cm overhang 3 x 2 turns around

Test : difficult because of the “clouds”in the lightpath

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Measurements | 0 | 0,43 | 1,3 | 2,26 | 3,0 | 3,6 | 4,2 mm |

| parabola | 0 | 1,52 | 2,80 | 4,08 | 5,33 | 6,60 | 7,78 mm |

Step 9

Jan. 31, 2006

25 cm starlap soft

a. Straight stroke with 2kg 0-5 cm from C and 5-8 cm overhang 10 mi

b. Straight stroke with 2 kg 2-5 cm from C and 5-8 cm overhang 15 min

c. Same as b, for 20 min.

d. Large W-stroke with 5-10 cm overhang :5 x 1 turn

I scratched the pitch squares to ensure an easier polishing action.

Ronchi : obvious bend in the lines at r=15 cm

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Measurements | 0 | 0,76 | 1,5 | 2,6 | 3,4 | 4,15 | 5,0mm |

| parabola | 0 | 1,52 | 2,80 | 4,08 | 5,33 | 6,60 | 7,78 mm |

Zone between 3 en 4

Hole in C

Step 10.

Now : how to get rid of the hole in the center and the bend at 15 cm?

For polishing I use Ceri-Hex from now on .This is more uniform but quite expensive stuff!

25 cm soft pitchlap(8 points star)

- Straight stroke 10-15 cm from C : 20 min

- Straight stroke 5-10 cm from C : 30 min

- large W-stroke 10x 1 turn around

Always with 2kg and 8-10 cm overhang. Polishing is only easy when I scratch the pitch squares.

Ronchi : looks regular

Fouc. 2 sets of measurements (30min in between)

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Measurements | 0 | 0,9 | 1,67 | 2,65 | 3,61 | 4,47 | 5,4mm |

| parabola | 0 | 1,52 | 2,80 | 4,08 | 5,33 | 6,60 | 7,78mm |

Step 11

Febr. 6, 2006

25 cm starlap 2 kg

- straight though center C : 10 min

- straight stroke 3-5 cm from C 2x 15 min

5- 10 cm overhang

3. straight stroke 10-15 cm from C 10 min

4. straight stroke 1-5 cm from C 15 min

5. large W-stroke 6×1 turn aound

Measurement:

First I turned down the central heating, closed the windows and waited for 3 hours!

Now the atmosphere was stable and I could make a good set of measurements.

Ronchi : regular

Fouc. 2-4 measurements d averaging

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| measurements | 0 | 0,7 | 1,12 | 2,34 | 3,28 | 4,38 | 5,37mm |

| parabola | 0 | 1,52 | 2,80 | 4,08 | 5,33 | 6,60 | 7,78mm |

Step 12.

Central area is too flat: deepen with 15 cm pointed lap.

- 15 cm lap + 2 kg straight stroke 1-3 cm from C and 5 cm overhang: 15 min

- 25 cm lap + 2 kg straight stroke 0-5 cm from C and 5-10 cm overhang

- 25 cm lap +2 kg large W-stroke 5-10 cm overhang : 5×1 turn around

- 15 cm lap : same as a

- 25 cm lap +2kg : straight stroke 0-15 cm from C and 5-10 cm overhang

It is also necessary to work on the outer zones!

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| measurements | 0 | 0,78 | 1,74 | 2,94 | 4,02 | 5,21 | 6,44 |

| parabola | 0 | 1,52 | 2,80 | 4,08 | 5,33 | 6,60 | 7,78 |

| Percent correction | 51 | 62 | 72 | 75 | 79 | 83 |

It looks like the edge zones are going flat!

Step 13

2 aims : increase correction and correcting long outer zones.

- 15 cm pointed lap + 2kg : straight stroke 0-3 cm from C : 20 min

- 25 cm starlap( already a bit thin!) + 2kg straight stroke on r=20-22 cm : 10 turns around

- 25 cm lap + 2 kg: straight stroke 0-5 cm from C and 8-10 cm overhang : 15 min

Ronchi : bend in lines at r=20 cm ; also low edge

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| measurements | 0 | 1,0 | 3,7 | 6,2 | 7,5mm | ||

| parabola | 0 | 1,52 | 2,80 | 4,08 | 5,33 | 6,60 | 7,78mm |

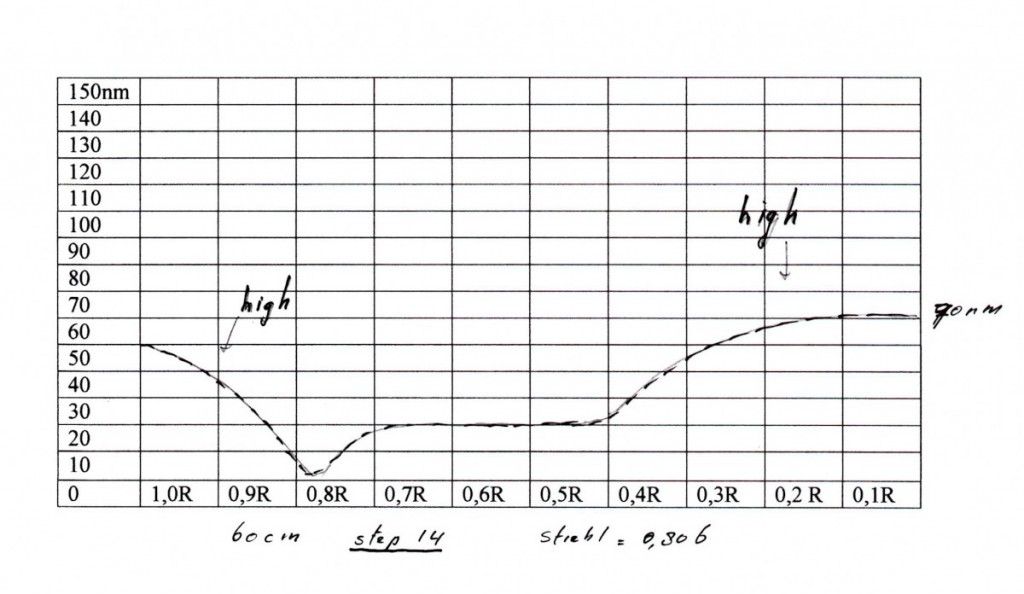

Step 14

Febr. 8, 2006

Aim: improve edge area and keep the amount of correction

- 15 cm starlap : Straight stroke on r=25 cm 10 turns around

- 15 cm sterlap : circular stroke r=25 to r=28 cm 15 min

- 15 cm sterlap : elliptical stroke r=-1 tot r=28 cm 20 min

Average of 2-5 measurements

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Measurements | 0 | 1,61 | 2,68 | 4,07 | 5,10 | 6,39 | 7,67 |

| Parabola | 0 | 1,52 | 2,80 | 4,08 | 5,33 | 6,60 | 7,78 |

Strehl = 0,755 labda/3.5 wavefront error

Figure: 0,1R means : 10 % of the radius from the center of the mirror

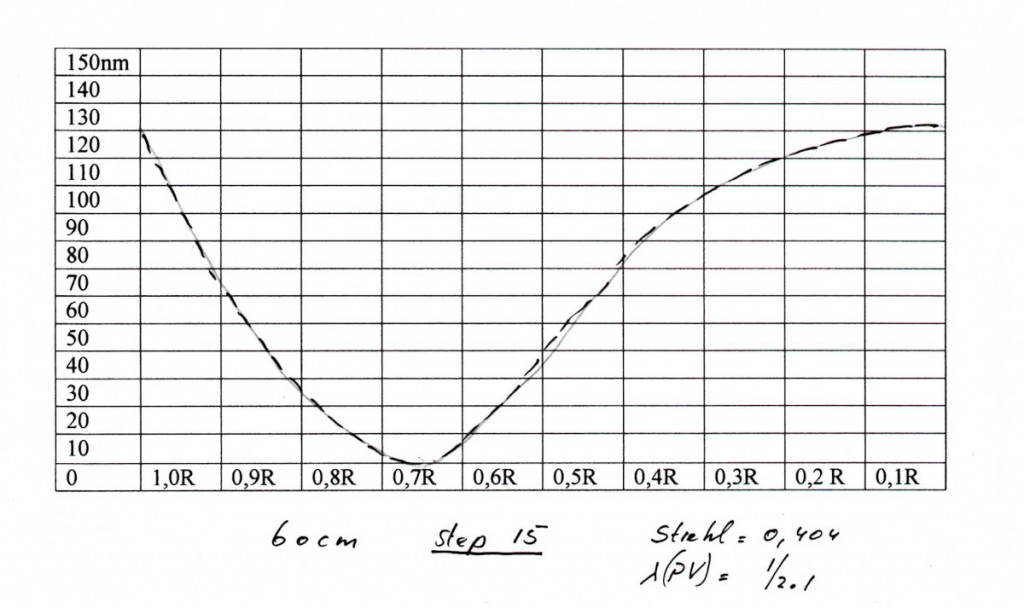

Step 15

Febr. 11, 2006

Plan : 1. correcting area r=27-30 cm

- correcting central area to r=10 cm

I use the old pitchlaps

- 10 cm lap circular stroke on r= 28-29 cm 10 turns around

- 15 cm lap +2 kg : narrow W-stroke between 5 cm left and 5 cm right of center:5 cm overhang : 5 min

- 25 cm lap large W- stroke 5-10 cm overhang 2×1 turn around

Ronchi : TDE?

Fouc.: Average of 3 measurements

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| measurements | 0 | 1,68 | 3,00 | 4,12 | 5,27 | 6,33 | 7,60mm |

| parabola | 0 | 1,52 | 2,81 | 4,09 | 5,34 | 6,61 | 7,78mm |

Strehl = 0,404 labda/ 2.1 Worked too much on C

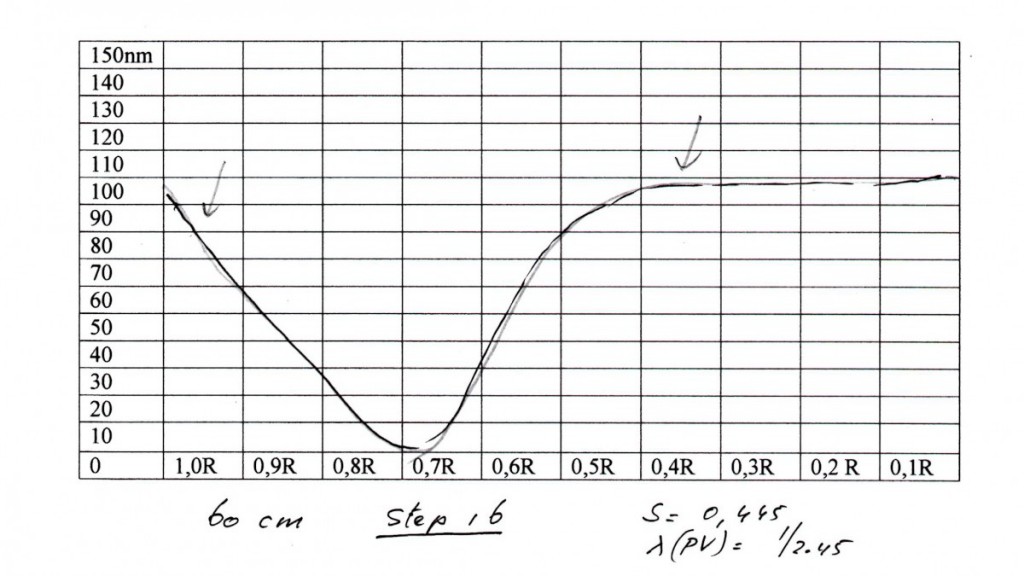

Step 16

Work more on edge

- 15 cm lap Tangential stroke on r=27 cm 5 turns around

- 15 cm lap Straight stroke on r=10-15 cm 5 turns around

- 25 cm starlap : large W-stroke concentrated on edge and center 4x 1 turn around

Ronchi : edge area flat and shallow hole in C

Foucault:

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| measurements | 0 | 1,74 | 3,04 | 4,21 | 5,24 | 6,41 | 7,77 |

| parabola | 0 | 1,52 | 2,81 | 4,09 | 5,34 | 6,61 | 7,78 |

Step 17

Febr. 15 , 2006

Work on edge

- 15 cm pointed lap 2 kg : tang .stroke on r=27 cm ;every 3 strokes one stroke to the center to get a bit of correction in that direction 10 min

- 15 cm lap + 2 kg W- stroke r=6 tot r=12 cm 4 turns around

- 25 cm starlap large W- stroke 3x 1 turn around

10 zone masker made

R=5213 mm

Average of 2 measurements

| zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Meas. | 0 | 1,31 | 2,23 | 3,21 | 3,84 | 4,81 | 5,31 | 6,11 | 6,87 | 8,05 |

| Parab. | 0 | 0,858 | 1,696 | 2,521 | 3,353 | 4,185 | 5,005 | 5,813 | 6,66 | 7,506 |

| procent |

I made new pitchlaps from Gugolz ,softened with linseed oil and turpentine.

Pressure test (Texereau) 1kg weight and 1 mm2 surface of pin :4 mm depth in 5 min.

Step 18

Work on r= 13,5 en r= 28 cm

First try with new 35 cm lap:

- very narrow W-stroke on r=27-29 cm (edge of tool on that area) : 6 turns around

- Narrow W-stroke on r=9-18 cm (edge of tool) : 5 turns around

- Large W-stroke ( smoothing) +2kg : 2 turns around with 8-10 cm overhang

I didn’t scrath the pitch squares, with the result that polishing didn’t go well

Test : zone 9-10 still 1,3mm difference!!

Difference 1-10 = 7,7 mm . Diff . 1-2 = 1,3 mm .There seems to be a TDE

Step 19

Work on TDE

With earlier mirrors I had great trouble combating this problem ; after using a small tool I had to go back to spherical because of the zoniness.

Try anyway..:

- 6 cm pointed lap: short tangential stroke on r=27 cm ;every 3 strokes a stroke to the center to prevent zones.. Light pressure 10 min

- 20 cm pointed lap +2 kg tangential stroke on r=25 cm ; every 3 strokes a stroke to the center ; 10 min

- 35 cm lap large W-stroke with 8-10 cm overhang : 3x 1 turn around

Ronchi : TDE en bend at r=15 cm

Fouc. : Total correction is 7.8 mm and diff 9-10 is 1.4 mm

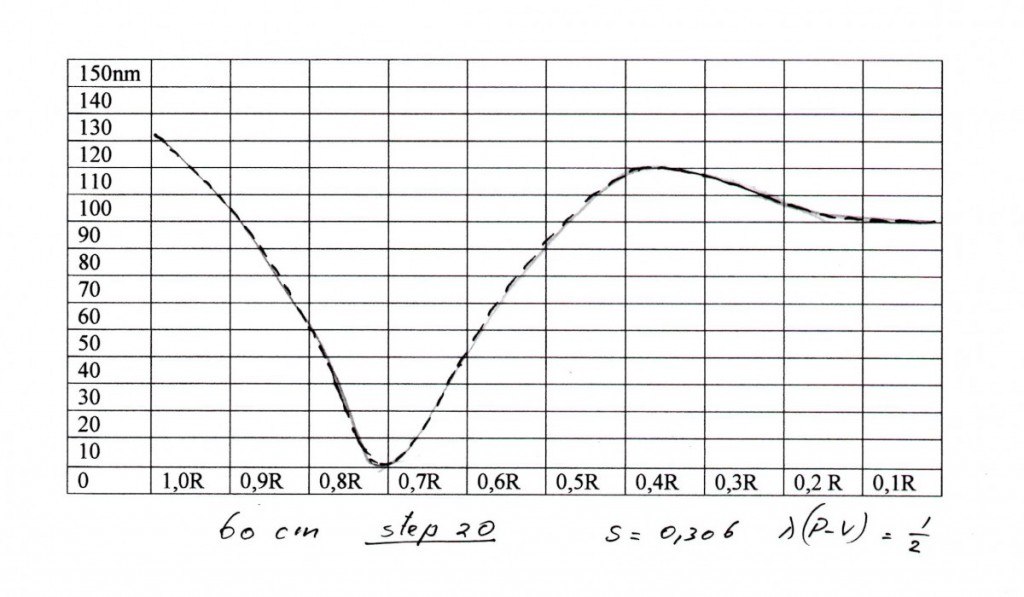

Step 20

Work on edge with several tools

- work with thumb on r=28 cm 5 turns around

- 15 cm pointed lap : circular stroke on r=27-28 cm with light pressure . 30 min Cold press every 5 minutes

- 15 cm pointed lap circular stroke on r= 15 cm 20 min with light pressure

- 15 cm pointed lap elliptical stroke on r=10 to r=28 cm

Ronchi: – small TDE

- Bend at r =16 cm

- Hole in C

Fouc. TDE less ! 2-4 measurements and averaging

| zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Meas. | 0 | 1,08 | 2,11 | 2,88 | 3,58 | 4,22 | 4,95 | 5,70 | 6,50 | 7,51 |

| Parab. | 0 | 0,858 | 1,696 | 2,521 | 3,353 | 4,185 | 5,005 | 5,813 | 6,66 | 7,506 |

| procent |

S= 0,306 labda/2

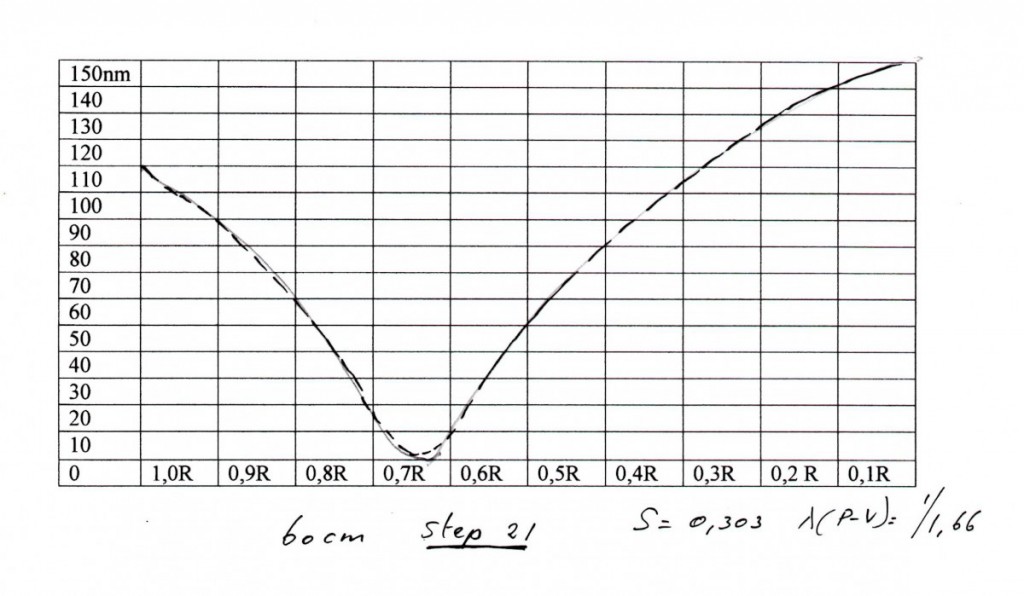

Step 21

Febr. 27, 2006

Work on edge and center

- 10 cm lap: circular stroke on r=27-28 cm ; light pressure: 15 min ;cold press every 5 min:

- 20 cm tool +2kg : W-stroke on r=9 to r=15 cm; 5-10 cm overhang: 15 min

- 20 cm tool : elliptical stroke on r=10 to r=25 cm ; light pressure : 15 min

Ronchi : TDE visible ; irregular surface in central area

Fouc. Average of 2-4 measurements

| zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Meas. | 0 | 0,74 | 1,59 | 2,38 | 3,03 | 3,73 | 4,48 | 5,33 | 6,12 | 7,18 |

| Parab. | 0 | 0,858 | 1,696 | 2,521 | 3,353 | 4,185 | 5,005 | 5,813 | 6,66 | 7,506 |

| procent |

Hole in center gone; TDE still around

Step 22

Febr. 28, 2006

Plan:

- Edge: 15 cm tool circular stroke with light pressure on edge : 15 min

- central area: 20 cm tool+ 2kg W-stroke within r=12 cm left and right ; 5-8 cm overhang : 15 min

- Edge: 15 cm tool : straight stroke on edge area; every 3 stroke a stroke to the center: 5 min

Ronchi : TDE + bend at r =15 cm

Fouc. Average of 2-4 measurements

| zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Meas. | 0 | 0,76 | 1,80 | 2,58 | 3,20 | 3,77 | 4,48 | 5,18 | 5,83 | 6,83 |

| Parab. | 0 | 0,858 | 1,696 | 2,521 | 3,353 | 4,185 | 5,005 | 5,813 | 6,66 | 7,506 |

| Percent corr.of the zone | 88 | 122 | 94 | 73 | 68 | 80 | 80 | 76 | 118 |

It’s worse,alas! S= 0,01 en labda/1

Step 23

March 1 ,2006

I am a bit in trouble. Edge no good and correction too small

- 20 cm pointed lap +2 kg : large W-stroke with 5-8 cm overhang.More pressure on edge and center : 3×14 min.

- 20 cm pointed lap : circular stroke with light pressure : r= -3 cm to r= +25 cm( that is : the center of the tool moves between those radii)

Ronchi : TDE + bend at r=15 cm

| zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Meas. | 0 | 0,84 | 1,82 | 2,76 | 3,55 | 4,18 | 4,67 | 5,26 | 6,20 | 7,07 |

| Parab. | 0 | 0,858 | 1,696 | 2,521 | 3,353 | 4,185 | 5,005 | 5,813 | 6,66 | 7,506 |

| Percent corr. | 98 | 115 | 112 | 95 | 75 | 60 | 73 | 111 | 102 |

S= 0,049 en labda/1,18

Conclusion; zones 6,7 and 8 radius too short ; too little correction.

Step 24

March 2, 2006

Try to work on the zones 6-8

- 20 cm pointed lap + 2 kg : W-stroke to max. r=25 cm(edge of tool goes to r =25 cm) : 35 min

- 10 cm tool : tangential stroke on r=28 cm ; every 3 strokes a stroke to the center: 11 min

- Smoothing with 35 cm tool : large W-stroke with 10 cm overhang :2x 1turn around

Ronchi : no improvement!

Foucault:

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Meas. | 0 | 0,57 | 1,35 | 2,21 | 2,97 | 3,80 | 4,44 | 5,14 | 5,90 | 6,87 |

| Parab | 0 | 0,858 | 1,696 | 2,521 | 3,353 | 4,185 | 5,005 | 5,813 | 6,66 | 7,506 |

| Percent corr. | 67 | 92 | 104 | 91 | 100 | 77 | 84 | 90 | 115 |

TDE present s= 0,318 labda/ 1,165

Step 25

March 2 , 2006

- Increase correction

20 cm pointed tool + 2 kg : straight stroke 0-5 cm from center and 5-8 cm overhang : 20 min

- Edge: 6 cm tool circular stroke on r =28 cm : 10 min.

- More correction and smoothing: 20 cm tool + 2 kg large W-stroke 5-8 cm overhang : 20 min

- Smoothing: 35 cm tool : large W-stroke 2 x1 turn around

Result : less correction! Caused bij large W-stroke? Surface zoned!

Average of 2 measurements

| zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Meas. | 0 | 0,43 | 1,3 | 1,84 | 2,68 | 3,28 | 4,21 | 4,79 | 5,61 | 6,40 |

| Parab | 0 | 0,858 | 1,696 | 2,521 | 3,353 | 4,185 | 5,005 | 5,813 | 6,66 | 7,506 |

| Percent corr. |

Step 26

March 4, 2006

Increase correction.

- 15 cm tool + 2kg straight stroke 1-2 cm from Center and 5 cm overhang: 15 min

- 25 cm tool + 2 kg straight stroke 0-5 cm from C : 15 min

- 25 cm + 2kg large W-stroke with 5-8 cm overhang : 15 min.

Measurements: 1 : 0 ; 2 : 0,71 ; 9 : 5,92 ; 10 : 6,86

Step 27

Increase correction

- 25 cm star shaped tool + 2 kg : straight stroke 0-5 cm from C and 5-8 cm overhang: 15 min

- Same tool: large W-stroke 5-8 cm overhang: 3×15 min.

Measurements: 1 : 0 ; 2 : 0,91 ; 9 : 6,16 10 : 7,21 Still a TDE

Step 28

- Improve edge: 6 cm tool : circular stroke on r=28 cm : 10 min

- Increase correction: 25 cm tool +2 kg : straight stroke 0-6 cm from C : 2x 15 min

- 25 cm starlap + 2 kg : large W-stroke 5-8 cm overhang 2x 15 min.

Measurements 1: 0 ; 2 : 0,60 ; 9 :5,98 ; 10 : 7,15

TDE and too little correction

Step 29

a. Work on TDE :15 cm pointed tool : circular stroke on r=27-28 cm : 5x 5 min

b. Increase correction and smoothing: 15 cm tool elliptical stroke from r = – 5 cm to r=27 cm : 5x 5 min

a and b are done in turn

Ronchi : bend at r=12 cm

Measurements : 1 : 0 ; 2 : 1,35 ; 9 : 6,76 ; 10 : 8,06

Edge still too flat!

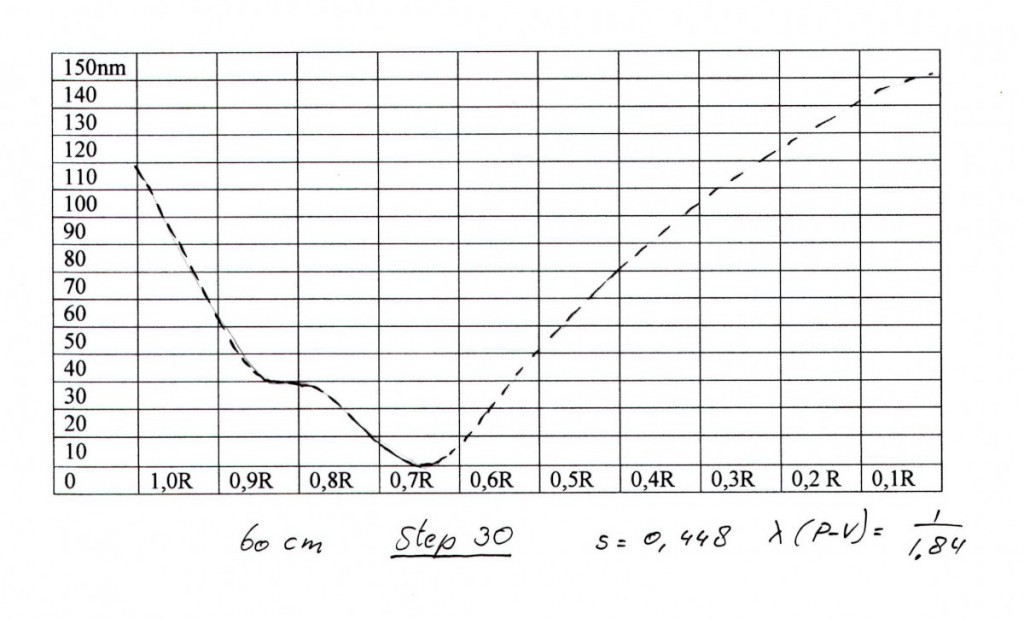

Step 30

Again: the TDE!

- 6 cm tool : tangential stroke on r=27-28 cm ;every 3 strokes a blending stroke veering off to the inside of the mirror 15 min.

- 6 cm tool : circular stroke on r=27-28 cm 20 min

- 35 cm tool : large W-stroke for smoothing: 1 turn around

Ronchi : hole in C ; bend at 20-22 cm

Foucault:

| zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Meas. | 0 | 0,74 | 1,50 | 2,30 | 2,95 | 3,64 | 4,69 | 5,47 | 6,01 | 6,94 |

| Parab. | 0 | 0,858 | 1,696 | 2,521 | 3,353 | 4,185 | 5,005 | 5,813 | 6,66 | 7,506 |

| Percent corr. |

Correction decreased

TDE less!

Zone in outer region of mirror

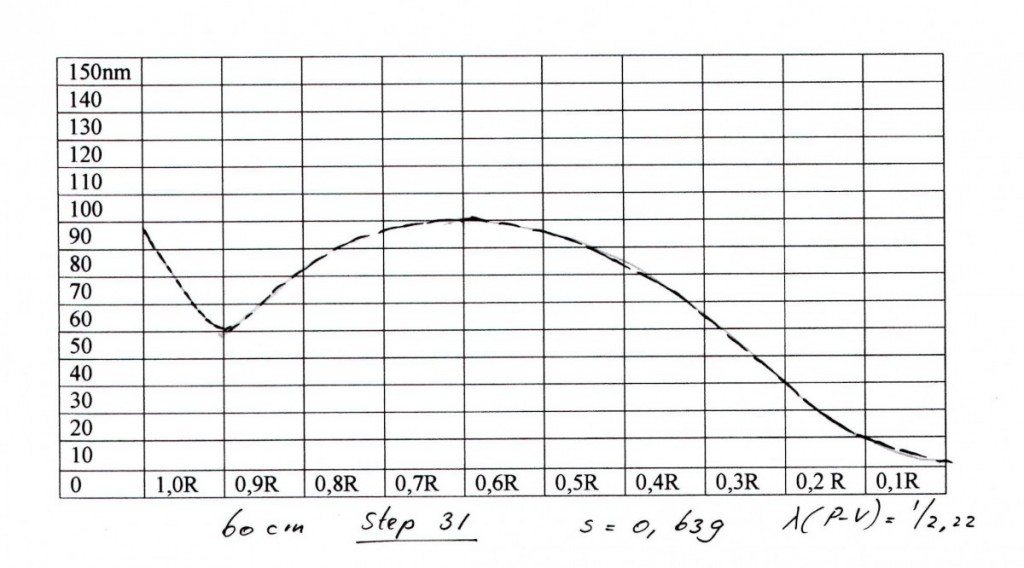

Step 31

- Thumbing on r=25 cm : 5 min

- further improvement of the edge:

a. 10 cm pointed lap tangential stroke on r=25-27 cm; every 3 strokes one stroke veering off aside to prevent a zone :………………………………… 15 min

b. 10 cm tool : circular stroke on r=27-29 cm ………………………15 min.

3. Increase correction : 20 cm pointed lap + 2 kg narrow W-stroke between r =5 en r= -5 cm and 5 cm overhang …………………………………30 min.

4. Smoothing with 35 cm tool+ 2kg : large W-stroke 5-8 cm overhang 2 turns around

Measurements: 8 o clock in the morning in closed house and no heating: Foucault image stable!!

Ronchi : hole in center and bend at r =22 cm

| zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Meas. | 0 | 0,99 | 2,06 | 2,92 | 3,79 | 4,56 | 5,61 | 6,37 | 6,91 | 7,71 |

| Parab. | 0 | 0,858 | 1,696 | 2,521 | 3,353 | 4,185 | 5,005 | 5,813 | 6,66 | 7,506 |

| Percent corr. | 115 | 127 | 104 | 104 | 92 | 127 | 93 | 62 | 95 |

Correction too large : 30 min was too long! Whole outer area irregular

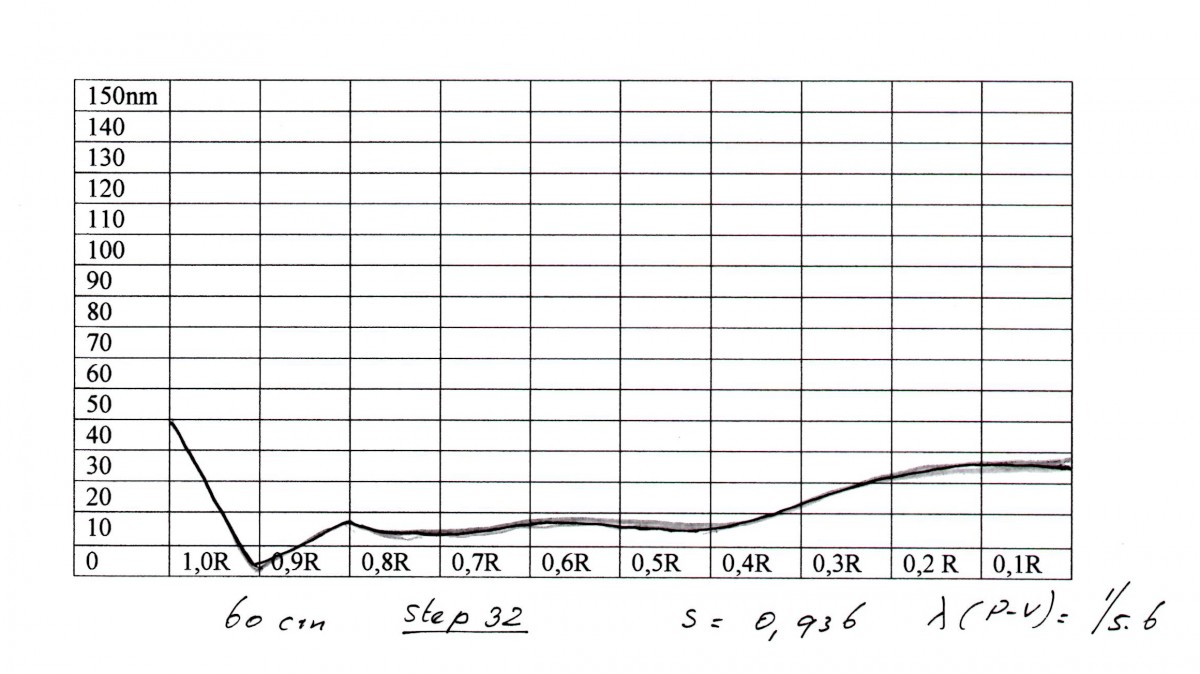

Step 32

I apply the radial stroke with the 35 cm tool to blend the zones.

Lap is placed in the center and moved to the edge; 10 cm overhang.

Move it back to the center and repeat in a different direction. 16 different positions in one turn around.

Total time 3x 5 min with pressing in between.

Ronchi : bend at r=22 cm

| zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Meas. | 0 | 0,78 | 1,56 | 2,43 | 3,18 | 4,03 | 4,89 | 5,80 | 6,38 | 7,20 |

| Parab. | 0 | 0,858 | 1,696 | 2,521 | 3,353 | 4,185 | 5,005 | 5,813 | 6,66 | 7,506 |

| Percent corr. | 90 | 92 | 105 | 90 | 102 | 105 | 107 | 68 | 98 |

Correction strongly decreased(was to be expected with the large tool)Hole in center gone

Zone still present

Step 33

- Increase correction : 20 cm pointed lap +2 kg : narrow W-stroke between r=- 6 and r=+ 6 cm ; 5 cm overhang…………..10 min

- 35 cm tool : radial stroke (see step 32) ………………..5 min

Ronchi : bend at r=22 cm

Fouc. 3-4 measurements “ spread” 0,05 mm

| zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Meas. | 0 | 0,85 | 1,74 | 2,55 | 3,43 | 4,24 | 5,18 | 5,92 | 6,56 | 7,31 |

| Parab. | 0 | 0,858 | 1,696 | 2,521 | 3,353 | 4,185 | 5,005 | 5,813 | 6,66 | 7,506 |

| Percent corr. |

Edge is “ rising”

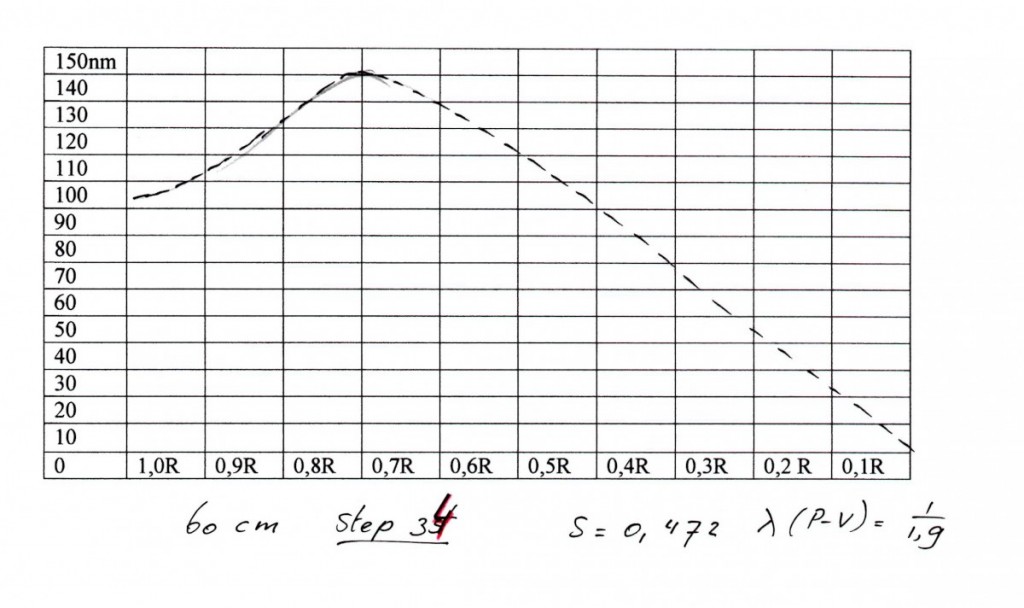

Step 34

Increase correction; less work on edge.

a. 25 cm starlap + 2 kg narrow W-stroke between r=-6 and r=+6 cm; 4 cm overhang : 10 min

b. 35 cm radial stroke with 4 cm overhang : 5 min

Fouc. 3-4 measurements :

| zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Meas. | 0 | 1,04 | 1,87 | 2,86 | 3,70 | 4,63 | 5,55 | 6,40 | 7,06 | 7,85 |

| Parab. | 0 | 0,858 | 1,696 | 2,521 | 3,353 | 4,185 | 5,005 | 5,813 | 6,66 | 7,506 |

| Percent corr. |

Too much correction and edge has risen

S= 0,472 en labda/1.9

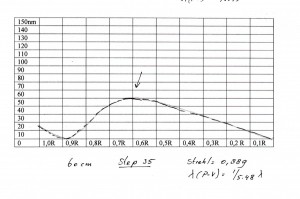

Step 35

35 cm lap + 2 kg : large W-stroke with 5-8 cm overhang: 2x ½ turn around(pressing in between)

4 measurements at 16 o’clock ( after 4 hours stabilizing)

| zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Meas. | 0 | 0,84 | 1,71 | 2,49 | 3,44 | 4,26 | 5,19 | 6,00 | 6,68 | 7,53 |

| Parab. | 0 | 0,858 | 1,696 | 2,521 | 3,353 | 4,185 | 5,005 | 5,813 | 6,66 | 7,506 |

| procent |

S= 0,889 labda/5,48

Great improvement!

Step 36

Work at 60-80 % radius

15 cm pointed lap (8 mm thick):

a.circular stroke at r=18-24cm;light pressure 5min

b. elliptical stroke from r= -1 to r=+20 cm; light pressure : 5 min

How the measurements are done:

- mirror on the stand in the bathroom; doors and windows closed

- 4 measurements

- Mirror is turned one quarter

- After 40 min again 2 measurements

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Meas. | 0 | 0,95 | 1,82 | 2,72 | 3,56 | 4,40 | 5,32 | 6,18 | 6,81 | 7,51 |

| Parab. | 0 | 0,858 | 1,696 | 2,521 | 3,353 | 4,185 | 5,005 | 5,813 | 6,66 | 7,506 |

| procent corr. |

S= 0,831 labda/3.9

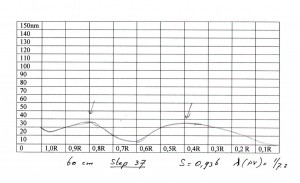

Step 37

In the Figure XP program one can choose the radius of curvature to make the correction of the figure easier.

If the edge is less turned up ( 20 nm in stead of 70 nm) ,than more work has to be done on r= 90 to r=240 mm. I am going to try that.

- 20 cm tool tangential stroke on r=150 mm; every 3 strokes one stroke veering off to the edge……………………….10 min

- 20 cm pointed lap+ 2 kg : elliptical stroke from r= 10 to r=28 cm…………10 min

test : average of 4 measurements

| zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Meas. | 0 | 1,15 | 1,87 | 2,54 | 3,36 | 4,18 | 5,14 | 6,03 | 6,73 | 7,54 |

| Parab. | 0 | 0,858 | 1,696 | 2,521 | 3,353 | 4,185 | 5,005 | 5,813 | 6,66 | 7,506 |

S = 0,936 labda/7.2

The worst of the measurements still delivers : s=0,931 and labda/6.7 on the wavefront

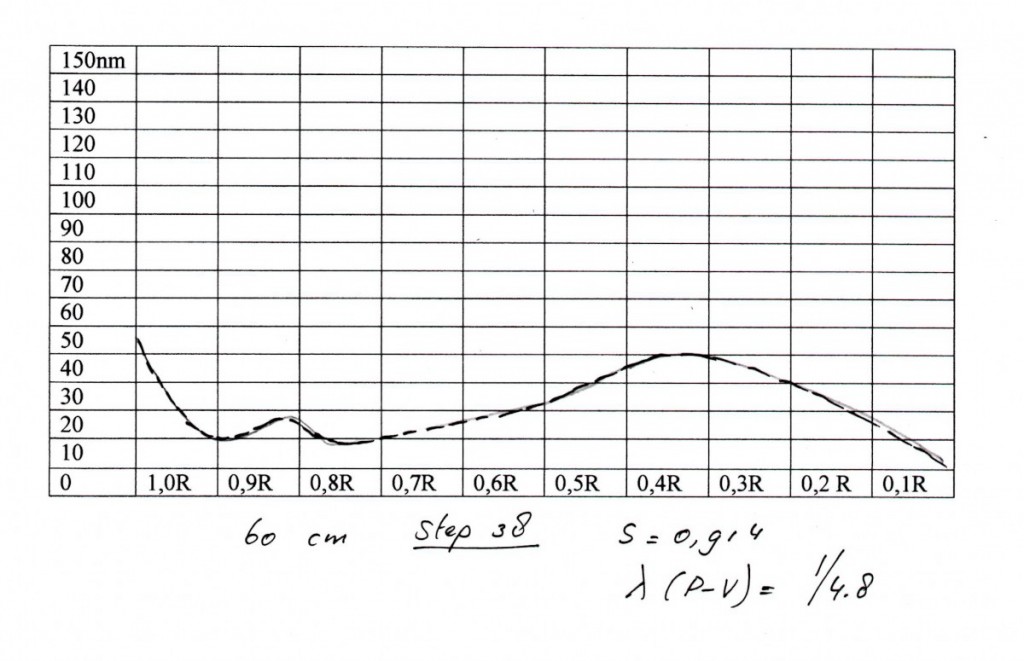

Step 38

May 24, 2007

10 cm tapered tool : work on the high zones in the figure

- Tangential stroke on r=240 mm: every 3 strokes a stroke veering off to the edge; light pressure ; ………………………………………………………5 min

- Elliptical stroke r=240 to r=270 m …………………………3 min

- Circular stroke r= 100 mm……………………………………3 min

- Elliptical stroke r= 50 to r=270 mm…………………………4 min

Test : average of 4-5 measurements

| zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Measurements | 0 | 1,09 | 1,85 | 2,67 | 3,51 | 4,24 | 5,12 | 5,96 | 6,66 | 7.39 |

| Parabola | 0 | 0,858 | 1,696 | 2,521 | 3,353 | 4,185 | 5,005 | 5,813 | 6,66 | 7,506 |

Undercorrected as a result of working on the outer zones

S= 0,914 en labda/4.8

Step 39

Work on the high zones

- 15 cm tool straight stroke on r=100 mm with 5 cm overhang; light pressure ….6 min

- elliptical stroke r=0 to r=230 mm………………………………………………3 min

| zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Meas. | 0 | 0,93 | 1,83 | 2,67 | 3,41 | 4,22 | 5,11 | 5,96 | 6,70 | 7,55 |

| Parab. | 0 | 0,858 | 1,696 | 2,521 | 3,353 | 4,185 | 5,005 | 5,813 | 6,66 | 7,506 |

S= 0,989 labda/ 14 PV

June 2, 2007 02.45

Startest : mirror in sling in 9 points cell

5 mm eyepiece : no astigmatism. Ronchi lines straight

Aluminium + QUARTZ LAYER : Galvoptics Basidon Essex (GB) : juli 2007

Price : 120 pounds only!